Note: All Orders Must Be Above £30.00.

No products in the basket.

Free Delivery from £75

To see if you are eligible for free delivery, read our delivery terms here.

In a busy commercial bakery, efficiency, safety and hygiene are not optional. They are foundations for delivering quality, maintaining compliance and protecting both customers and staff.

At Creeds Direct, our range of colour-coded utensils is designed to help bakery operations adhere to the highest food safety standards, streamline workflow and reduce the risk of cross-contamination.

Here’s why colour coding has become a must in modern kitchens, how to implement it well and how our equipment helps.

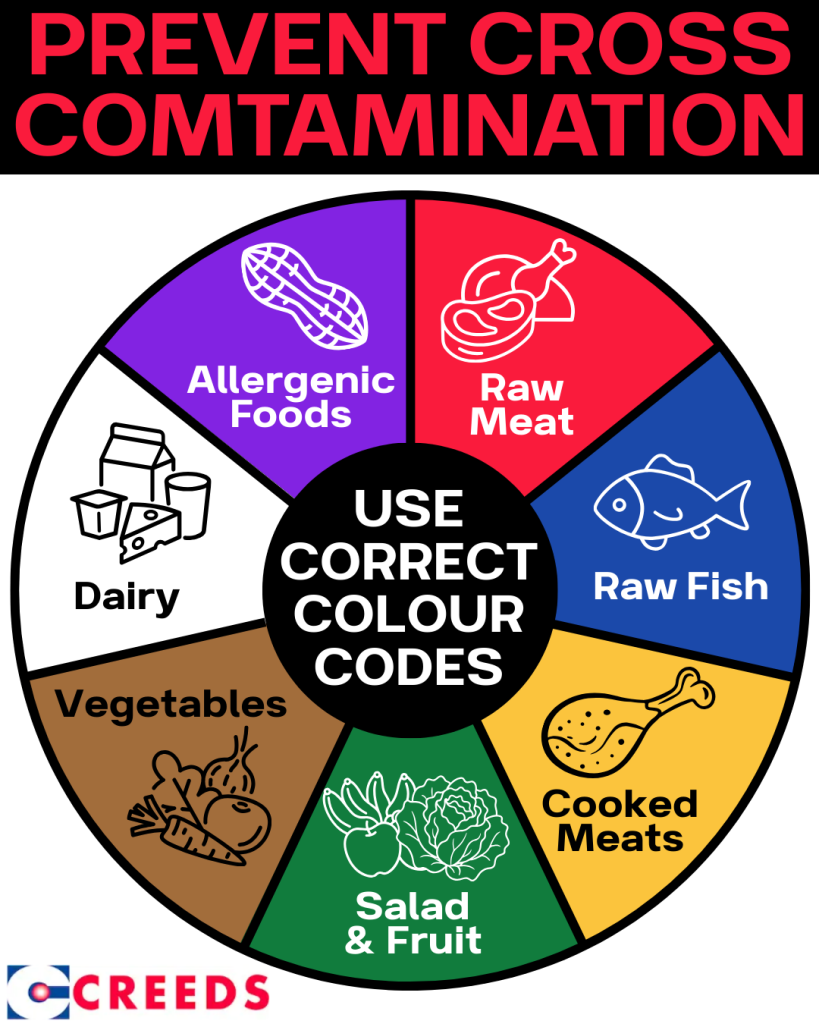

Colour-coded utensils are tools (like chopping boards, scoops, brushes, scrapers and thermometers.) that are assigned specific colours according to their use (raw meat, cooked food and allergenic foods).

The aim is to keep different processes and food types clearly separated, thereby preventing cross-contamination of bacteria, allergens or unwanted residues. At Creeds Direct, all our colour-coded equipment is HACCP-compliant.

HACCP stands for Hazard Analysis and Critical Control Point. It’s a food safety system that helps businesses spot and control risks before they become a problem. Instead of waiting for something to go wrong, HACCP takes a preventative approach.

It looks at every stage of food handling:

At each step, potential hazards are identified and ‘critical control points’ are set up to make sure food stays safe.

In a bakery, it only takes one slip-up for ingredients to mix where they shouldn’t. Imagine a scoop used for flour ending up in the nut storage or a knife that cut raw meat being used on pastry.

Colour-coded utensils act as a simple safeguard, helping your team instantly spot the right tool for each task and protecting your customers from hidden risks.

No one likes dreading an inspection. With a clear colour-coding system in place, you can show environmental health officers that your bakery is serious about food safety.

Colour-coded boards, scrapers and scoops are a straightforward way to demonstrate HACCP compliance and keep your processes audit-ready without adding extra stress.

Bakeries are busy, and often seasonal staff or trainees join during peak times. Colour-coding makes training quicker and easier, allowing new team members to see at a glance which tools go where. That means fewer mistakes, less waste and a smoother workflow when every second counts.

With the growing number of customers asking for nut-free, gluten-free or dairy-free products, allergen management is more important than ever. Having dedicated utensils for allergenic ingredients shows your customers you care about their safety.

It also gives you confidence that when you label a product ‘allergen-free’ you truly mean it.

A bakery that visibly takes its hygiene seriously inspires confidence. Regular customers or clients will appreciate transparent safety practices. Having well-organised, labelled tools contributes to an impression of professionalism.

Using a consistent scheme helps everyone in the kitchen immediately identify the correct tool, especially under busy or pressured conditions.

Start by walking through your bakery’s daily routine. Where are the biggest risks? Maybe it’s raw ingredients stored close to baked goods or the same scraper used across multiple stations.

Spotting these pain points will help you decide which utensils you need in which colours.

Once you’ve assigned your colours, make the rules easy for everyone to follow. A simple wall chart in the prep area or above storage racks works wonders.

The clearer your system, the less chance there is for mistakes when things get busy.

Nothing slows down a bakery like sharing tools between jobs. Make sure you’ve got enough colour-coded equipment for each area.

Creeds Direct offers full ranges in multiple colours, so you’ll never be short when you need a dedicated tool at hand.

Even the best system won’t work if your team isn’t on board. Build colour-coding into your training for new starters and refresh the basics with your regular staff.

This doesn’t have to be complicated! A quick reminder at the start of a shift or a visual guide in the kitchen is often all it takes.

Give every utensil its own place. Wall hooks, labelled racks or coloured containers make it obvious where each tool belongs. That way, staff don’t waste time searching and there’s less risk of the wrong utensil ending up in the wrong place.

In a bakery, tools take a beating. Boards get scratched, scrapers wear down and colours fade. When that happens, hygiene can slip. Build regular checks into your routine and replace worn utensils before they become a problem.

Don’t just set the system and forget it. Every few weeks, take a moment to check if your team is following the colour code properly. If you spot shortcuts or confusion, adjust your process or add more utensils where needed. Over time, this keeps your bakery running smoothly and safely.

Equipping your bakery with the right colour-coded tools helps you keep hygiene under control and your workflow smooth. Here are Creeds Direct, we stock all the essentials to consider:

Colour-coded utensils are more than just a nice-to-have in modern commercial bakeries. They are an essential part of food safety, allergen control, operational efficiency and regulatory compliance.

At Creeds Direct, our extensive range of colour coded utensils help you design a system that suits your kitchen’s specific needs. With proper policies, training and maintenance, those tools will safeguard your bakery’s hygiene standards, boost staff confidence and ultimately support consistent, high-quality output.

Browse our full range of colour coded utensils today or contact us for expert advice.