Note: All Orders Must Be Above £30.00.

No products in the basket.

Free Delivery from £75

To see if you are eligible for free delivery, read our delivery terms here.

Running a high-volume bakery means every second counts. Efficiency, consistency and speed are the cornerstones of success. That’s why investing in the right commercial bakery equipment isn’t just practical – it’s essential.

In this guide, we’ll explore the top 5 time-saving bakery tools every busy bakery should consider. From mixing to proofing, each machine plays a key role in boosting output without compromising quality.

Dough mixers are essential for high-volume bakeries because every bakery begins with dough. Without the right mixer, production slows to a crawl. A professional dough mixer delivers consistency, speed and versatility.

Each has unique strengths. Choosing the right type ensures smoother workflow and minimises delays.

Why it saves time: Large-capacity bowls, powerful motors and consistent kneading eliminate manual effort and reduce prep time.

Discover more about dough, heated and planetary mixers here.

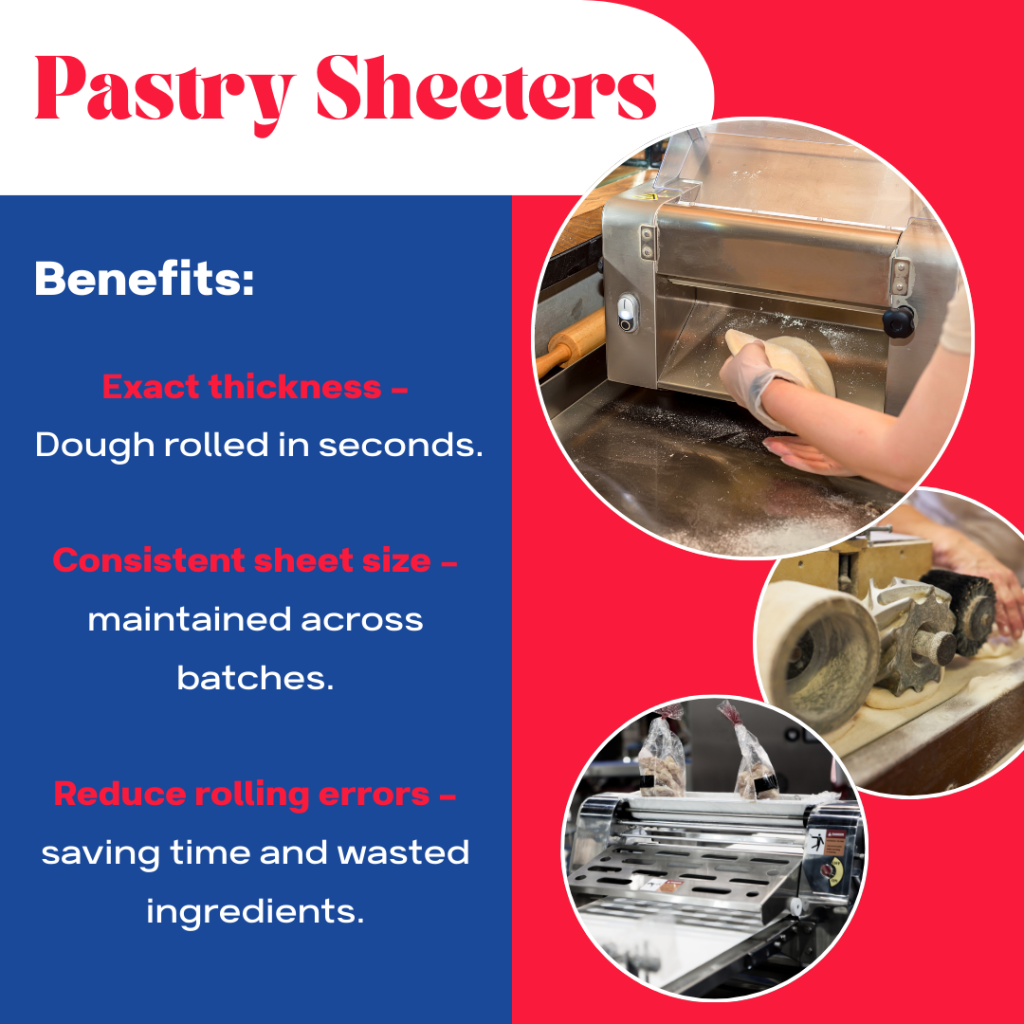

Pastry sheeters improve bakery efficiency by creating uniform dough sheets quickly, ensuring pastries rise evenly in the oven.

Laminated doughs demand precision. Croissants, puff pastry and Danish pastries all need uniform layering. Enter the pastry sheeter.

Whether crafting buttery croissants or crisp mille-feuille layers, a sheeter turns hours of manual labour into minutes.

Why it saves time: Eliminates manual rolling, reduces repetitive strain and guarantees precision across high-volume orders.

Discover more about dough and pastry sheeters here.

Dough dividers and rounders enable consistent bakery production by providing automated accuracy. Alternatively, portioning dough by hand is slow and inconsistent.

High-volume bakeries need dough dividers and rounders to keep production flowing.

Each option caters to different scales of production. Choosing the right one ensures both accuracy and efficiency.

Why it saves time: Uniform sizing cuts down on weighing, reduces mistakes and speeds up production lines.

Discover more about choosing the right dough moulder for your bakery here.

Proofing cabinets provide the environment for fermentation, which is essential for dough development. But inconsistent room temperatures can wreak havoc on proofing times.

Proofing cabinets provide controlled environments, ensuring consistency across every batch.

They’re essential for bakeries producing bread, rolls and laminated doughs at scale.

Why it saves time: Eliminates guesswork, reduces waiting and ensures products move seamlessly from prep to bake.

Learn more about bakery proofing cabinets here.

The best multi-function ovens for commercial bakeries deliver versatility and capacity. No bakery thrives without the right oven. For high-volume operations, multi-function ovens are essential.

Whether you’re baking delicate pastries or crusty loaves, there’s an oven built for the task.

Why it saves time: Large capacity, even baking and multi-programme settings reduce errors and shorten bake cycles.

Read more on bakery oven types and their uses at Creeds Direct.

Bakery efficiency machines are vital for growth because each one plays a role in streamlining bakery operations. Together, they transform output, consistency and overall workflow.

In a competitive market, bakery efficiency machines aren’t just useful. They’re vital for growth.

High-volume bakeries thrive on efficiency. From mixers to ovens, every machine covered here brings speed, precision and consistency to the table.

At Creeds Direct, we supply professional commercial bakery equipment designed for demanding environments. Each product is built to save time, cut costs and deliver outstanding results.

Tired of doing everything by hand? Explore our full range of bakery machines and contact us today for expert advice.